What is the difference between meltblown fabric and nonwoven fabric?

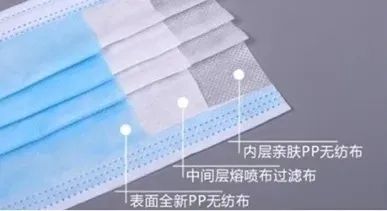

Meltblown fabric is mainly made of polypropylene as the main raw material, and the fiber diameter can reach 1~5 microns.

With more voids, fluffy structure and good wrinkle resistance, these ultra-fine fibers with unique capillary structure increase the number of fibers per unit area and surface area, thus making meltblown fabric have good filtering,

shielding, adiabatic and oil absorption properties.

It can be used in the fields of air and liquid filtration materials, isolation materials, absorbent materials, mask materials, warming materials, oil absorbent materials and wiping cloths.

1. Application scope.

(1) Medical and health care fabrics: surgical gowns, protective clothing, disinfection wraps, masks, diapers, women’s sanitary napkins, etc.

(2) Home decoration fabrics: wall coverings, tablecloths, bed sheets, bedspreads, etc.

(3) with the clothing cloth: lining, bonded lining, wadding, shaped cotton, various synthetic leather base cloth, etc.

(4) Industrial fabrics: filter materials, insulation materials, cement bags, geotextiles, coverings, etc.

(5) Agricultural fabrics: crop protection cloth, rice planting cloth, irrigation cloth, insulation curtain, etc.

(6) Others: space wool, thermal insulation materials, oil-absorbing felt, cigarette filters, bags of tea bags, etc.

Meltblown cloth filter material is made of polypropylene ultra-fine fibers randomly distributed dip knotted together, the appearance of white, flat,

soft, material fiber fineness of 0.5-1.0μm, the random distribution of fibers provides more opportunities for thermal bonding between fibers, thus making meltblown gas filter material has a larger specific surface area, higher porosity (≥75%).

After high pressure electret filtration efficiency, the product has the characteristics of low resistance, high efficiency and high dust capacity.

Nonwoven fabrics, also known as nonwoven fabrics, are made up of oriented or random fibers. It is called cloth because it has the appearance and certain properties of cloth.

Nonwoven fabric is moisture-proof, breathable, flexible, light, non-combustible, easy to decompose, non-toxic and non-irritating, colorful, inexpensive, recyclable and other characteristics. Such as the use of polypropylene (pp material) granules as raw materials, by high-temperature melting, spraying silk, laying outline, hot pressing rolled continuous one-step production.

2. Nonwoven fabric characteristics.

Non-woven fabric has no warp and weft thread, cutting and sewing are very convenient, and it is light and easy to set, so it is loved by handicraft lovers.

Because it is a kind of fabric formed without spinning and weaving, only the textile short fibers or filaments are oriented or randomly arranged to form a fiber network structure, and then reinforced by mechanical, thermal or chemical methods.

It is not made of one by one yarn interwoven and braided together, but the fibers are directly bonded together by physical methods, so when you get the sticky weigh in your clothes, you will find that it is impossible to draw a single thread.

Nonwoven fabric breaks through the traditional textile principle and has the characteristics of short process flow, fast production rate, high yield, low cost, wide application and many sources of raw materials.

The relationship between nonwoven and spunbond

punbond and nonwovens are subordinate to each other.

There are many production processes for the manufacture of nonwovens, among which spunbond is one of the nonwoven production processes 3.Nonwoven fabric characteristics.

Nonwoven fabric is moisture-proof, breathable, flexible, light, non-combustible, easy to decompose, non-toxic and non-irritating, colorful, inexpensive, recyclable and other characteristics. Such as the use of polypropylene (pp material) granules as raw materials, by high-temperature melting, spraying silk, laying outline, hot pressing rolled continuous one-step production.

Non-woven fabric has no warp and weft thread, cutting and sewing are very convenient, and it is light and easy to set, so it is loved by handicraft lovers.

(Including spunbond, meltblown, hot-rolled, spunlace, most of the nonwoven fabrics on the market are produced by spunbond method)

According to the composition of nonwoven fabrics, there are polyester, polypropylene, nylon, spandex, acrylic, etc.;

different compositions will have very different styles of nonwoven fabrics. As for spunbond cloth, it usually refers to polyester spunbond and polypropylene spunbond; and the styles of these two cloths are very close to each other and can only be distinguished by high temperature testing.

Nonwoven fabric is a kind of nonwoven fabric, which is a non-woven fabric formed by directly using polymer slices, short fibers or filaments to form fibers into a web by airflow or machinery,

then by hydroentanglement, needle punching, or hot rolling reinforcement, and finally by finishing.

With soft, breathable and flat structure of new fiber products, the advantage is that it does not produce fiber chips, strong,

durable, silky soft, but also a kind of reinforcing material, and there is the feeling of cotton, and compared with cotton woven products, non-woven bags are easy to form, and the cost is cheap.

3. Advantages of non-woven fabrics.

1. Light weight: The main raw material is polypropylene resin, the specific gravity is only 0.9, only three-fifths of cotton, with fluffiness, good hand feeling.

2. Soft: Made of fine fibers (2-3D) with light dotted hot-melt bonding. The finished product is moderately soft and has a comfortable feeling.

3. Water repellent and breathable: polypropylene slices do not absorb water, the water content is zero, the finished product has good water repellence, and is composed of 100% fibers with porosity, good breathability, easy to keep the surface of the cloth dry and easy to wash.

4. Non-toxic, non-irritating: The product is produced with FDA food-grade raw materials and does not contain other chemical ingredients, with stable performance, non-toxic, odorless and non-irritating to the skin.

5. Antibacterial, chemical resistance: polypropylene is a chemically blunt substance, not insects, and can isolate the presence of bacteria and insects within the liquid erosion; antibacterial, alkali corrosion, finished products do not affect the strength due to erosion.

6. Antibacterial. The products have water pulling, no mold, and can isolate the bacteria and insects in the liquid, no mold.

7. Good physical properties. The strength of the product is better than the general staple fiber products, and the strength is non-directional, and the strength is similar in both vertical and horizontal directions.

8. In terms of environmental protection, the raw material of most of the non-woven fabrics used is polypropylene, while the raw material of plastic bags is polyethylene, although the names of the two substances are similar,

but the chemical structure is very different.

Polyethylene’s chemical molecular structure has a fairly strong stability, extremely difficult to degrade, so plastic bags need 300 years to decompose; while the chemical structure of polypropylene is not strong, the molecular chain can easily break, which can be effectively degraded,

and in a non-toxic form into the next step in the environmental cycle, a non-woven shopping bags in 90 days can be completely decomposed. And non-woven shopping bags can be reused more than 10 times, and the pollution of the environment after disposal is only 10% of plastic bags.

By Coco Ho

By Coco Ho