Non-woven masks

There are two kinds of non-woven masks, one is made of cotton skimmed gauze or knitted fabric on the surface, with various non-woven fabrics in the middle;

the other is sewn directly from non-woven fabric. It has good filtration effect and slightly poor ventilation.

The latest varieties are non-woven material on the surface and back, and filter paper in the middle, thus making the non-woven mask filtering effect a higher level.

Medical protective masks technical requirements of the relevant documents issued by the General Administration of Quality Supervision, Inspection and Quarantine on April 29, 2003, and began to implement on the same day.

Contents

- 1 1. Non-woven mask use method

- 2 2. Dust-blocking efficiency of non-woven masks

- 3 3. Non-woven masks are not suitable for people

- 4 4.1 of this standard is recommended, the rest is mandatory.

- 5 5. Non-woven masks test methods

- 6 6. Instructions for use of non-woven masks

- 7 7. Non-woven mask packaging, transportation and storage

- 8 8. Non-woven masks selection skills

- 9 9. Non-woven mask type

1. Non-woven mask use method

So, for the choice of filtering masks to use, some manufacturers’ products give you the following convenience, that is, you can use the same mask body,

when in the dusty operating environment need to dust, with the corresponding filter cotton, so that you wear a dust mask;

when the need to be in a toxic environment for drug prevention, change the filter cotton, installed with the corresponding chemical filter cartridge,

so that it becomes a drug mask again, or according to your work needs, to provide you with more combinations.

2. Dust-blocking efficiency of non-woven masks

The efficiency of a nonwoven mask is based on its ability to block fine dust, especially respirable dust below 5 microns.

This is because dust of this size can enter the alveoli directly and has the greatest impact on human health. The general gauze mask,

its dust blocking principle is mechanical filtration, that is, when the dust rushes to the gauze, after – layer after layer of blocking, some large particles of dust will be blocked in the sand cloth. However, for some fine dust,

especially dust less than 5 microns, it will pass through the mesh of the gauze and enter the respiratory system.

Now there are some foreign dust masks, the filter media is filled with permanent electrostatic fiber composition,

those smaller than 5 microns of respiratory dust in the process of passing through such filter media,

electrostatic attraction and adsorption in the filter media to capture the fine dust, really play a dust-blocking role.

Air is like water flow, where the resistance is small, it flows first. When the shape of the non-woven mask does not fit the human face,

the dangerous things in the air will leak in from the unsealed place and enter the human respiratory tract.

Then, even if you choose a good filter material mask. You can not protect your health. Many foreign regulations and standards stipulate that workers should be regularly tested for the tightness of non-woven masks.

The purpose is to ensure that workers choose the right size of non-woven mask and follow the correct steps to wear the mask.

The requirements are low breathing resistance, light weight, hygienic wear and easy maintenance.

This way, workers will be happy to wear it in the workplace and improve their efficiency.

Now foreign maintenance-free masks, no need to clean or replace parts, when the dust barrier saturation or mask broken that is discarded, so as to ensure the hygiene of non-woven masks and eliminate the time and energy of workers to maintain the mask.

And many masks use arch shape, which can ensure a good fit with the shape of the face and can keep a certain space at the non-woven mask, comfortable to wear.

3. Non-woven masks are not suitable for people

People with heart or respiratory system difficulties (such as asthma emphysema), pregnant women, dizziness after wearing, breathing difficulties and skin sensitivity, etc.

The outer layer of the non-woven mask tends to accumulate a lot of dirt such as dust and bacteria in the outside air,

while the inner layer blocks the exhaled bacteria and saliva, therefore, the two sides cannot be used alternately, otherwise the dirt stained on the outer layer will be inhaled into the body when it is directly close to the face, and become a source of infection.

When the mask is not worn, it should be folded into a clean envelope and folded inward on the side that is close to the nose and mouth,

do not just stuff it into a pocket or hang it around the neck.

This standard is used to evaluate the quality of medical protective masks.

4.1 of this standard is recommended, the rest is mandatory.

Production units since the date of implementation of this standard according to this standard organization production, distribution units from June 15, 2003 onwards.

This standard is proposed by the State Food and Drug Administration.

This standard is attributed by the Beijing Municipal Medical Device Testing Institute.

This standard drafting unit: the Beijing Municipal Medical Device Testing Institute.

The main drafter of this standard: Zhang Zhaoyuan, Bi Chunlei, Liao Xiaoman, Yan Xue, Zeng Ning.

Technical requirements for medical protective masks

4. Non-woven mask range of application

This standard specifies the basic requirements of medical protective masks (hereinafter referred to as masks), test methods, marking and instructions for use and packaging, transportation and storage.

This standard applies to self-absorbing filtered dustproof medical protective masks that can filter particles in the air and block droplets, blood, body fluids, secretions, etc.

5. Non-woven masks test methods

Be careful of the basic size of 1 mask

Measured with common gauges and shall conform to Article 4.1.

Be careful2 Appearance

Visual inspection shall be in accordance with Article 4.2.

Be careful 3 Nose clip

By inspection and measured by general or special gauges, it shall comply with Article 4.3.

Be careful with 4 mask straps

A total of 4 masks shall be tested. 2 with temperature pre-treatment and 2 without pre-treatment.

Be careful with the 5 filtration efficiency and airflow resistance tests

Six mask filter media should be used for filtration efficiency test. three after temperature pretreatment and three without pretreatment.

6. Instructions for use of non-woven masks

Select 1 Marking

Select 1.1 The minimum packaging of the mask should have at least the following clearly identifiable markings, and if the packaging is transparent, the markings should be visible through the packaging.

Select 1.2 There should be at least the following content or markings on the packaging box.

7. Non-woven mask packaging, transportation and storage

Borrow 1 Packaging

Borrow 1.1 The packaging of the mask should be able to prevent mechanical damage and contamination before use.

Borrow 1.2 Mouthpieces are boxed in quantity, put in the certificate of conformity (packing list) and sealed.

Borrow 2 Transportation

Under the conditions specified in the contract.

Borrowing 3 Storage

8. Non-woven masks selection skills

Follow the instructions for use. There are various kinds of disposable dust masks, which must be selected for different operational needs and working conditions.

The first should be selected according to the concentration and toxicity of dust. According to GB/T18664 “Selection, use and maintenance of respiratory protective equipment”,

as half masks, all dust masks are suitable for environments where the concentration of hazardous substances does not exceed 10 times the occupational exposure limit,

otherwise a full face mask or respirator with a higher level of protection should be used.

If the particulate matter is highly toxic, carcinogenic and radioactive, the filter material with the highest level of filtration efficiency should be selected.

If the particles are oily, be sure to choose the appropriate filter material.

If the particulate matter is needle-like fibers, such as slag cotton, asbestos, glass fiber, etc.,

because the dust mask can not be washed, sticky tiny fibers in the face sealing parts of the mask easy to cause facial irritation, also not suitable for use.

For high temperature and high humidity environment, choose a mask with exhalation valve will be more comfortable, c

hoose a mask that can remove ozone for welding can provide additional protection,

but if the ozone concentration is higher than 10 times the occupational health standards can replace the mask with a combination of dust and toxic filter elements.

For the environment where there are no particles but only certain odors,

it is much lighter to choose a dust mask with an activated carbon layer than to wear a gas mask, such as certain laboratory environments,

but because national standards do not regulate the technical performance of such masks. The best choice is to try it first to determine whether it can really filter the odor effectively. Whether the dust mask really plays a protective role, in addition to the selection of protective features, another important selection factor is suitability.

There is no one-size-fits-all design that will fit everyone’s face.

Certification testing of dust masks does not guarantee that the mask will fit every specific user, and if there is a leak, airborne contaminants can enter the breathing zone through the leak.

The way to choose a suitable mask is to use the fit test, which uses the human sense of taste to occur bitter or sweet tasting particles with a special tool.

If the taste can still be felt after wearing the mask, it means there is a leak in the mask, please refer to the introduction of the fit test in GB/T18664 for details.

9. Non-woven mask type

Non-woven mask mask type One of the non-woven masks, the strap type non-woven mask is more flexible and the degree of wearing elasticity varies from person to person.

The material is made of pure cotton skimmed gauze or knitted fabric with non-woven fabric in the middle, which has good filtration effect but poor breathability.

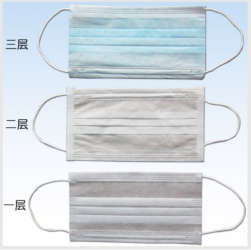

The latest non-woven masks, the surface layer is non-woven, the middle is the filter layer, generally using meltblown cloth as the filter layer, strong breathability, filtration effect is also good, and has sterilization effect.

Non-woven masks are the most widely used category in our daily work.

The structure of a non-woven mask should be divided into two major parts, one is the main body of the mask, we can simply understand that it is a mask frame;

the other is the filter material part, including the filter cotton for dust control and the chemical filter box for anti-toxic, etc.

By Coco Ho

By Coco Ho