Nonwoven Fabric Buying Guide

White Paper: melt blown Nonwoven Fabric

Melt blow extrusion is one of the manufacturing processes used to make nonwoven fabrics. These fabrics are made of polymers, such as polypropylene (PP). Nonwoven fabrics do not involve knitting or yarning. However, the fibers are joined together through thermal, chemical, or mechanical bonding methods.

The resulting fabrics often come with desirable properties that make them suitable for various applications. Some of the properties of nonwoven fabrics include filtration, absorbency, sterility, strength, resilience, washability, etc.

What Is Melt-Blown Nonwoven Fabric?

The melt-blown process is one of the manufacturing processes used to make nonwoven fabrics. The process involves the direct conversion of polypropylene and other polymers into filaments. These filaments or fibers are joined together using a bonding agent to form a web of fibers.

Melt-blown nonwoven fabric is a material made through the melt-blow process. The material is called nonwoven because it is made directly from fibers that do not go through processes, such as spinning, yarning, or knitting.

Melt-blown nonwoven fabrics are produced from thermoplastic synthetic polymers.

Classification of Melt Blown Nonwoven Fabrics

Melt-blown nonwoven fabric is a flexible fibrous material made through the melt-blown method. Accordingly, melt-blown nonwoven fabrics can be classified according to their uses. In this case, the categories include melt-blown nonwoven fabrics for face masks, melt-blown nonwoven fabrics for filtration, melt-blown nonwoven fabrics for purifiers, melt-blown nonwoven fabrics for insulation, and melt-blown nonwoven fabrics for absorption.

Additionally, it can be classified as:

- Melt-blown nonwoven fabrics are used to make different types of face masks, anti-particulate respirators, and filtration products.

- Melt-blown nonwoven fabrics are used to make thermal insulation and heat preservation products, such as garments and warm flakes.

- Melt-blown nonwoven fabrics are used to make air purifiers, such as air conditioners for purifying the air.

- Melt-blown nonwoven fabrics for oil absorption products, such as mats and ropes.

Uses of Melt Blown Nonwoven Fabrics

Melt-blown nonwoven fabrics are used in various applications, producing products used in the agricultural, construction, roofing, carpeting, automotive, and medical industries. Here are some specific examples of products manufactured using melt-blown nonwoven fabrics.

Melt-blown nonwoven fabrics are highly porous, which allows them to filter liquids and gases. They are used in applications, such as water treatment, making face masks, and air conditioners.

One of the properties of melt-blown nonwoven is retaining liquids, especially when made of polypropylene. This makes them ideal for making oil-absorbing products to reduce contamination.

Personal hygiene products

Due to high absorption, melt-blown nonwoven fabrics are used to make personal hygiene products, such as wet wipes and disposable diapers.

Thermal insulation, breathability, and moisture resistance are the properties that make nonwoven fabric suitable for making clothing.

Melt-blown products can be loaded with fibers used in drug delivery.

Industries That Depend On Melt Blown Nonwoven Fabrics

As suggested earlier, melt-blown nonwoven fabric manufacturers can design many products used in a wide variety of industries. The applications of nonwoven fabric made through the melt-blown process are closely related to the uses. The industries that depend on melt-blown nonwoven fabrics include:

- Medical industry: the manufacture of medical protective products, such as surgical masks and gowns, protective clothing, sanitary napkins, etc.

- Home decoration fabrics: production of bed sheets, table mats, table cloths, wall stickers, etc.

- Clothing industry: producing lining, flakes, adhesive lining, etc.

- Industrial fabrics: manufacturing HEPA filters, insulation products, geotextiles, etc

- Agricultural industry: producing irrigation cloth, thermal insulation curtains, seedling covers, etc.

Melt-Blown Nonwoven Fabrics for Making Face Masks

Melt-blown nonwoven fabric is a type of polypropylene spun bond nonwoven used as a filter material in the production of face masks.

Melt-blown nonwoven fabric is also called spun-bound non-woven fabric. The primary material used to make this fabric is polypropylene, with a diameter that can reach 5 microns. The fabric has many voids, wrinkle resistance, fluffy structure, and capillary structure that make it excellent for filtration and absorption required in a mask material.

The Mask Making Process

All the steps needed in that mask-making process are automated using the mask-making machine. Here are the basic steps followed in making industrial and medical masks:

- The first step includes combining the layers to produce a multi-layered fabric. The mask-making machine feeds the fabric together into a layered structure.

- Attaching the metal nose strip follows. In this stage, the machine stitches the metal wire into the multi-layered fabric. This strip is used to improve the mask’s fit.

- Adding fold and creases. A folding device is used to add creases and folds to make the mask adjustable.

- Cutting and stitching. The mask material is cut into individual masks and stitched to join the layers to the edges.

- Attaching ear loops. After cutting the mask material, ear loops are added using adhesive. Some nonwoven mask manufacturers use ultrasonic welding to attach ear loops.

- Disinfection. Medical masks are sterilized using ethylene oxide. After this, the mask is left for a week to dissipate the ethylene oxide, which is harmful to humans.

- Packaging. The last step is to package the masks ready for delivery.

All cup-shaped masks and respirators are manufactured following the same processes but with different machines and materials.

All medical face masks are made using nonwoven polypropylene fabric, which has excellent filtration properties. Additionally, the fabric has a random orientation due to the extrusion process. This enhances the density of the fabric to improve its ability to filter out microparticles. These properties make melt-blown nonwoven fabrics ideal for filtering bacteria, viruses, and other pathogens.

The Bottom Line

Melt-blown nonwoven fabric is made through the melt-blown extrusion process. This fabric comes with many desirable properties that make it ideal for producing various products used in many industries. Some of the applications of nonwoven melt-blown fabric include the medical, agricultural, and personal hygiene sectors. Due to their excellent structure, these products are used mainly to filter out microparticles, absorb moisture, and protect against pathogens.

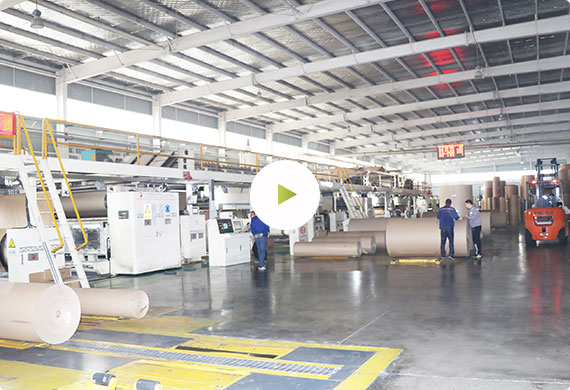

Melt-blown nonwoven fabric is one of the most used materials in making nonwoven products. With this material, melt-blown nonwoven fabric manufacturers can produce hundreds of thousands of nonwoven products daily. If you want to buy melt-blown nonwoven fabric, make sure you check out the manufacturing facility to determine the manufacturer’s ability to meet your requirements.