How are high quality meltblown fabrics made?

Nowadays, the production of meltblown fabric has long passed the early profitable era, basically the current competition is the quality of the process, and the production of meltblown fabric as a very typical manufacturing industry, the control of the entire work chain is very important.

What we need to do is to control the five factors of human, machine, material, method and environment well in order to improve the quality up.

1. people: operators’ awareness of quality, technical proficiency, physical condition, etc.

2. machines: the precision of machines and equipment, measuring instruments and the state of maintenance, etc.

3. materials: the composition, physical and chemical properties of materials, etc.

4. methods: including production processes, equipment selection, operating procedures, etc.

5. environment: the temperature, humidity and cleaning conditions of the workplace, etc..

Of the above five major elements, the lack of one, that the whole link will affect the quality of our production.

Contents

I. Factors of operators (human)

1 Production personnel need to go through relevant training and examination, and meet the corresponding job skills requirements.

2 Special processes need to be clearly defined, and inspection personnel should also have the corresponding professional operating skills.

3 Operators need to maintain a strict and cautious mindset, abide by the company system and operate strictly according to the process documents in a step-by-step manner, and treat their work seriously and responsibly.

4 Inspection personnel strictly in accordance with the process procedures and inspection instructions to carry out inspections, make the original records of inspection and submit them in accordance with the regulations.

Second, the factors of machinery and equipment (machine)

1. Equipment management measures need to be formulated well in advance, which include the acquisition, flow, maintenance, repair and verification of equipment need to be clearly defined.

2. All provisions of the equipment management measures must be effectively implemented with equipment ledgers, equipment skill files, maintenance verification plans and related records.

3. Production equipment, inspection equipment, tooling, measuring instruments, etc.

are in accordance with the requirements of the process procedures and can meet the requirements of the process capability.

If the processing conditions change over time, adjustments and compensation can be made in time to ensure quality requirements.

4. Production equipment, inspection equipment, tooling, measuring instruments, etc. are in good condition.

Third, the material factor (material)

1. Have a clear and feasible management system for material purchase, storage, transportation and quality inspection.

2. Establish incoming inspection, warehousing, storage, identification and distribution system, and carefully implemented to strictly control quality.

3. The processed semi-finished and finished products meet the quality requirements and have batch or serial number identification.

4. Have clear responsibility for non-conforming product control methods, can effectively isolate, identify, record and deal with non-conforming products.

5. Effective management of production material information and traceability of quality issues.

Fourth, the factors of the process method (law)

1. The process layout is scientific and reasonable to ensure product quality meets the requirements.

2. Able to distinguish critical process, special process and general process, effectively establish process quality control points, and clearly identify the process and control points.

3. Have formal and effective production management methods, quality control methods and process operation documents.

4, the main processes have operating procedures or operating instructions, operating documents for personnel, tooling, equipment, operating methods, production environment, process parameters and other specific technical requirements.

In addition to the clarification of process parameters, but also to develop process rules, for special processes, should also specify the process parameters, sample preparation, working media, equipment and environmental conditions control methods.

V. Factors of the environment (ring).

1. The production site has an environmental health management system.

2. Environmental factors such as temperature, humidity and light meet the requirements of production technical documents.

3. There are relevant safety and environmental protection equipment and measures in the production environment, and the health and safety of employees meet the requirements of laws and regulations.

4. The production environment is kept neat and orderly, and there is no clutter not related to production. We can learn from 5S related requirements.

5. Materials, semi-finished products, utensils, etc. are placed and stored neatly.

6. Can effectively fill in or obtain the relevant environmental records.

VI. Production process of meltblown fabric

Screw extruder: melts the chips.

Metering pump:controls the output and the fineness of the fibers to deliver the melt continuously to the spinneret.

Melt filter:Filter the impurities from the melt.

Conveying screen curtain:makes meltblown fibers evenly received spread on the screen

Spinning box: so that after the fiber is ejected, immediately after the airflow stretching with high speed hot air, the fiber is blown off and become ultra-fine fiber.

Feeding system: consists of three measuring hoppers, which are used to measure white chips, masterbatches and additives respectively.

Hot fan and heater: provide the temperature and pressure of the hot air used in spinning airflow stretching, with electric heating, power consumption is large.

Winding machine: fully automatic winding is used to pack the meltblown fabric into rolls.

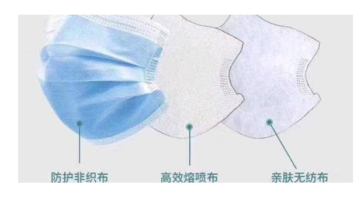

Meltblown fabric is mainly made of polypropylene, and the fiber diameter can reach 1 to 5 microns.

Since the raw material of meltblown fabric, polypropylene, is taken from oil, so petrochemical companies have an advantage in the production of meltblown fabric.

By Coco Ho

By Coco Ho